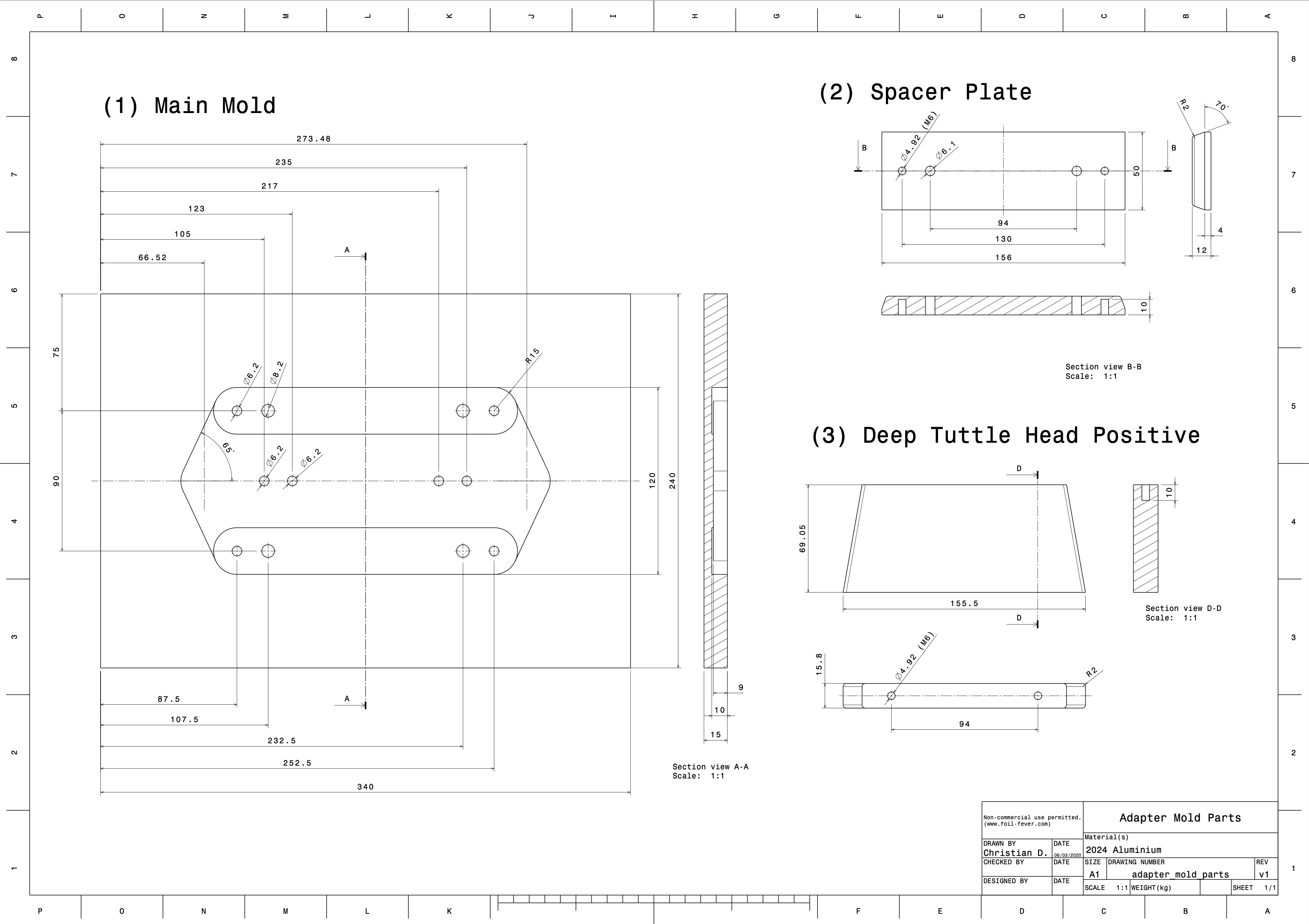

To use a board with a rail system or the foiling power plate with a deep tuttle head foil mast an adapter is needed. Most manufacturers sell them as accessories to their foils but since I had plenty of time while waiting for my foil order to arrive I decided to make one myself. The design is somewhat similar to the GROOVE Deep Tuttle Adapter as you might notice.

There are nice forum posts of 'sharksupper' where he shows how he made such adapter without the help of a mold. Since I had an NC mill at hand I decided to make a simple mold system to get a precise result and to reduce the required sanding.

The mold system only helps with the the mounting slit of the foil's tuttle head and the mounting surface to the board, the rest of the adapter has to be hand-formed.

Milling the deep tuttle adapters, one of which one was later used for making deep tuttle board inserts for my Fanatic Skate and my JP Magic Ride.

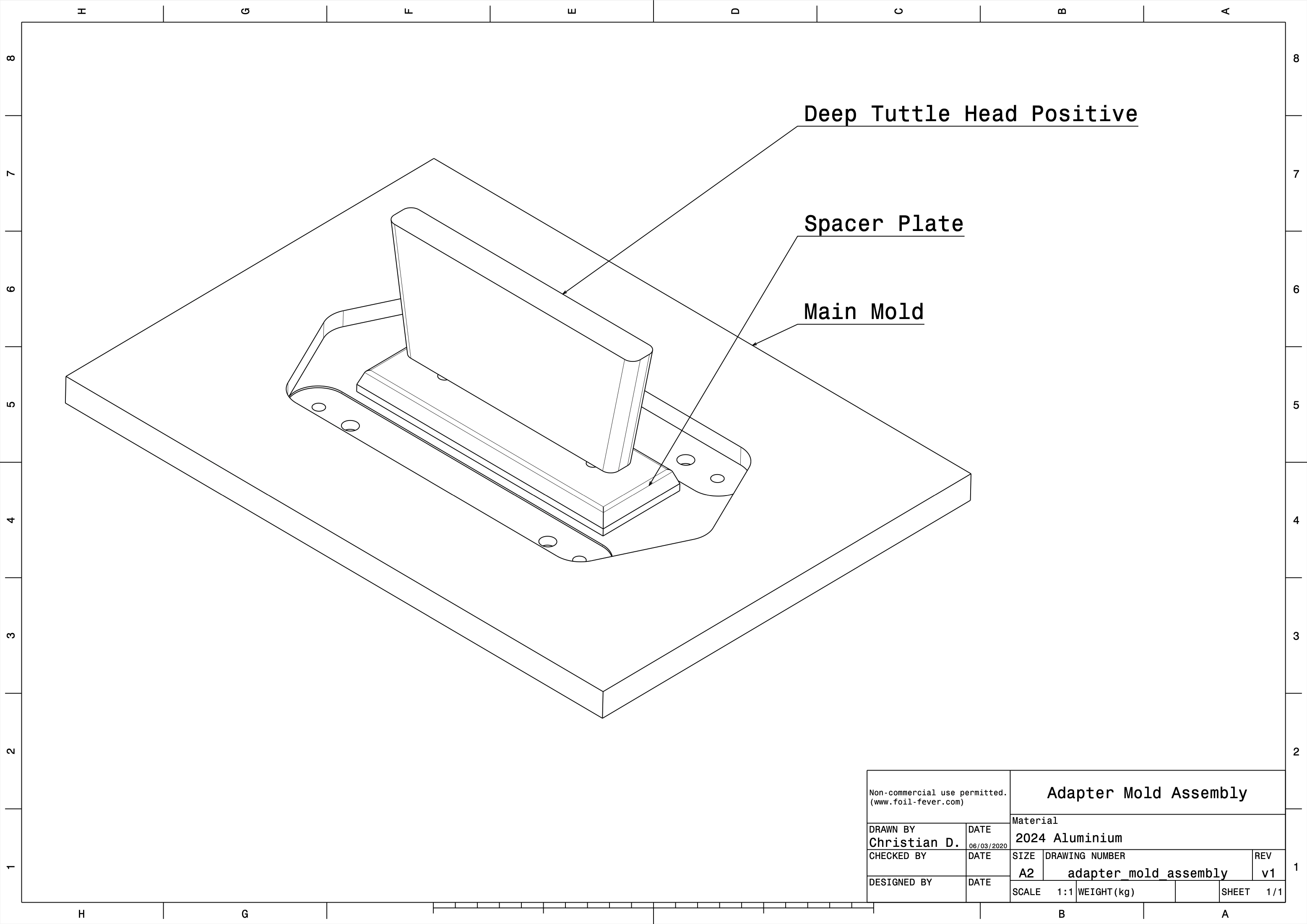

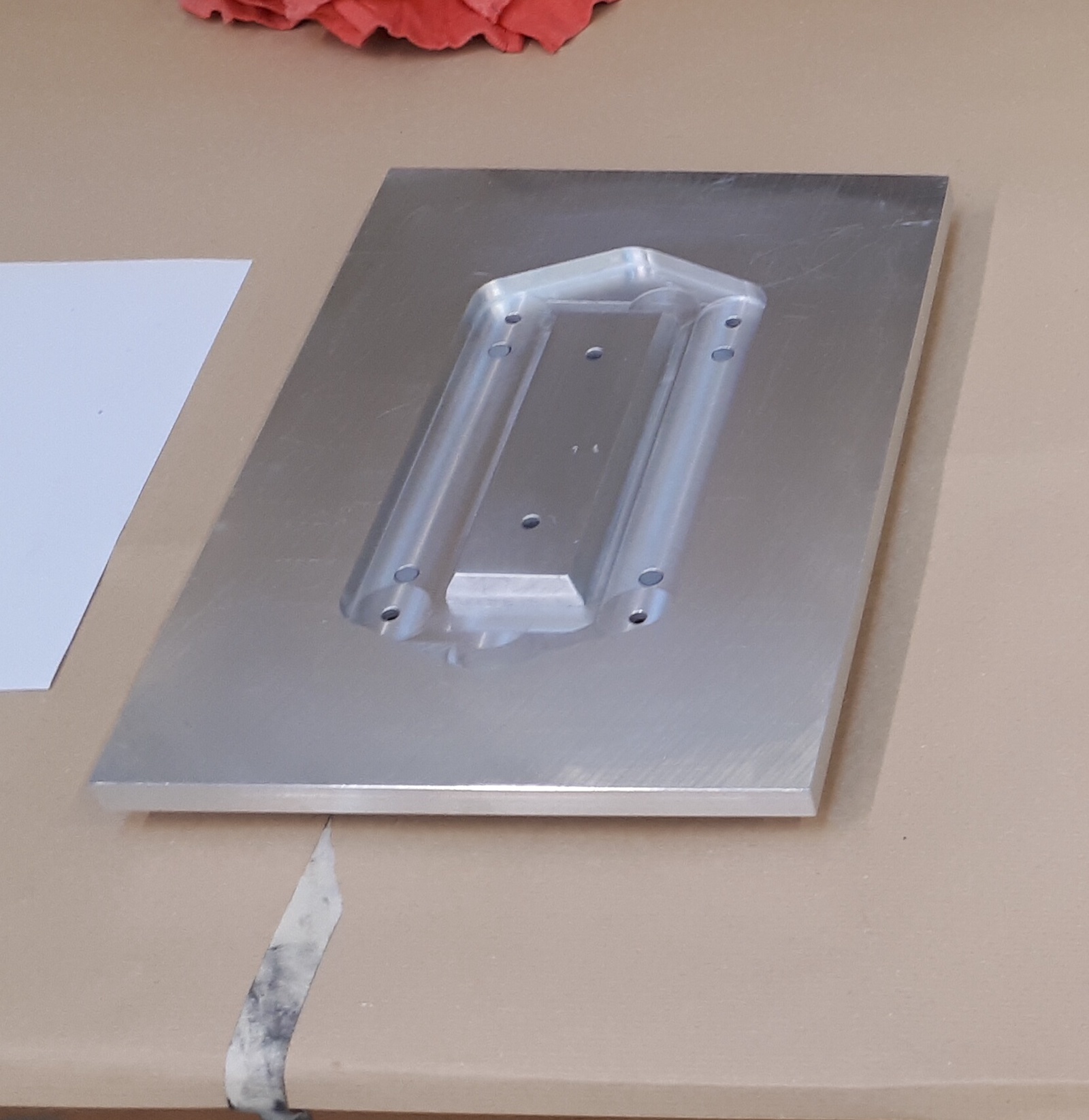

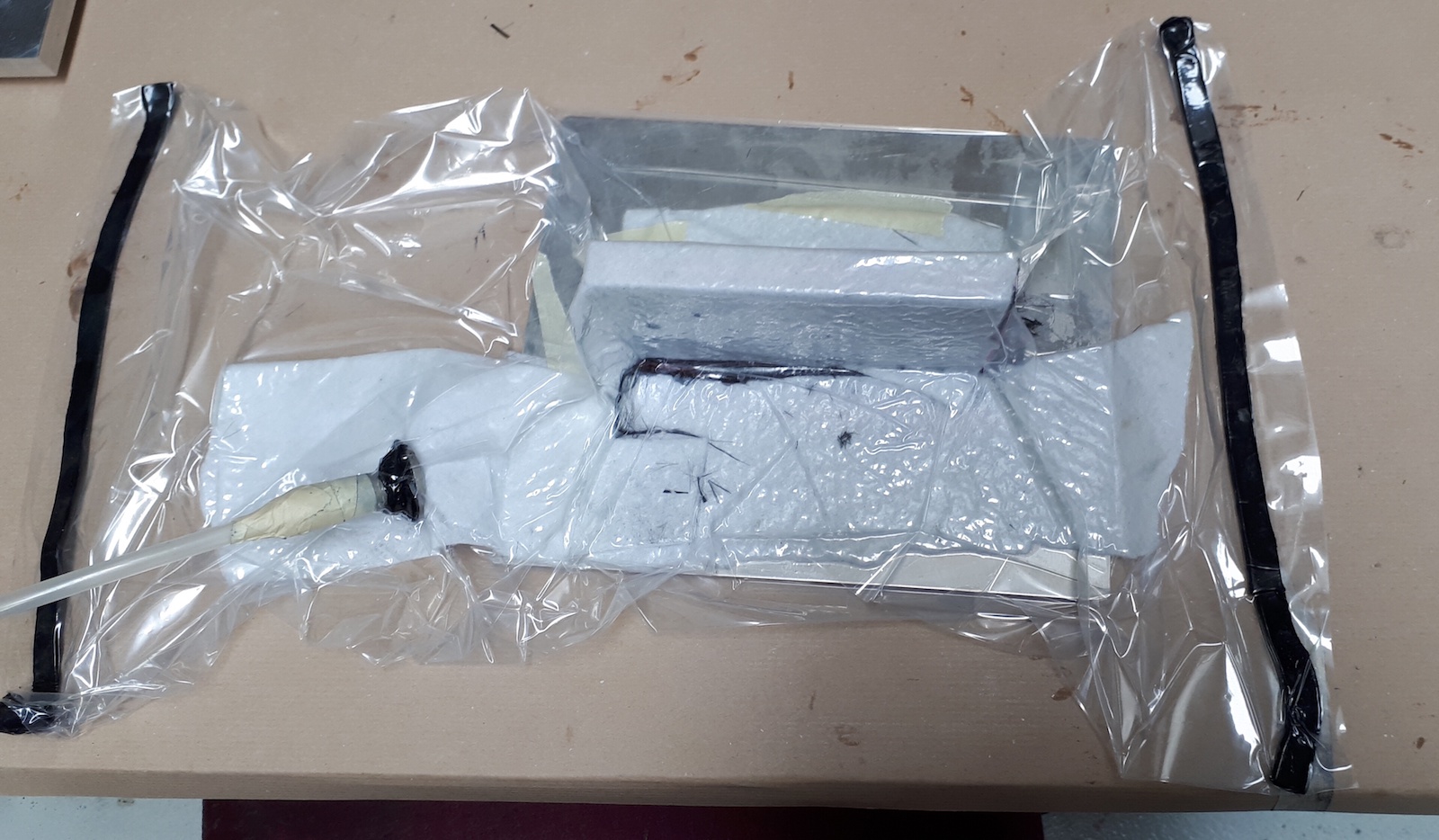

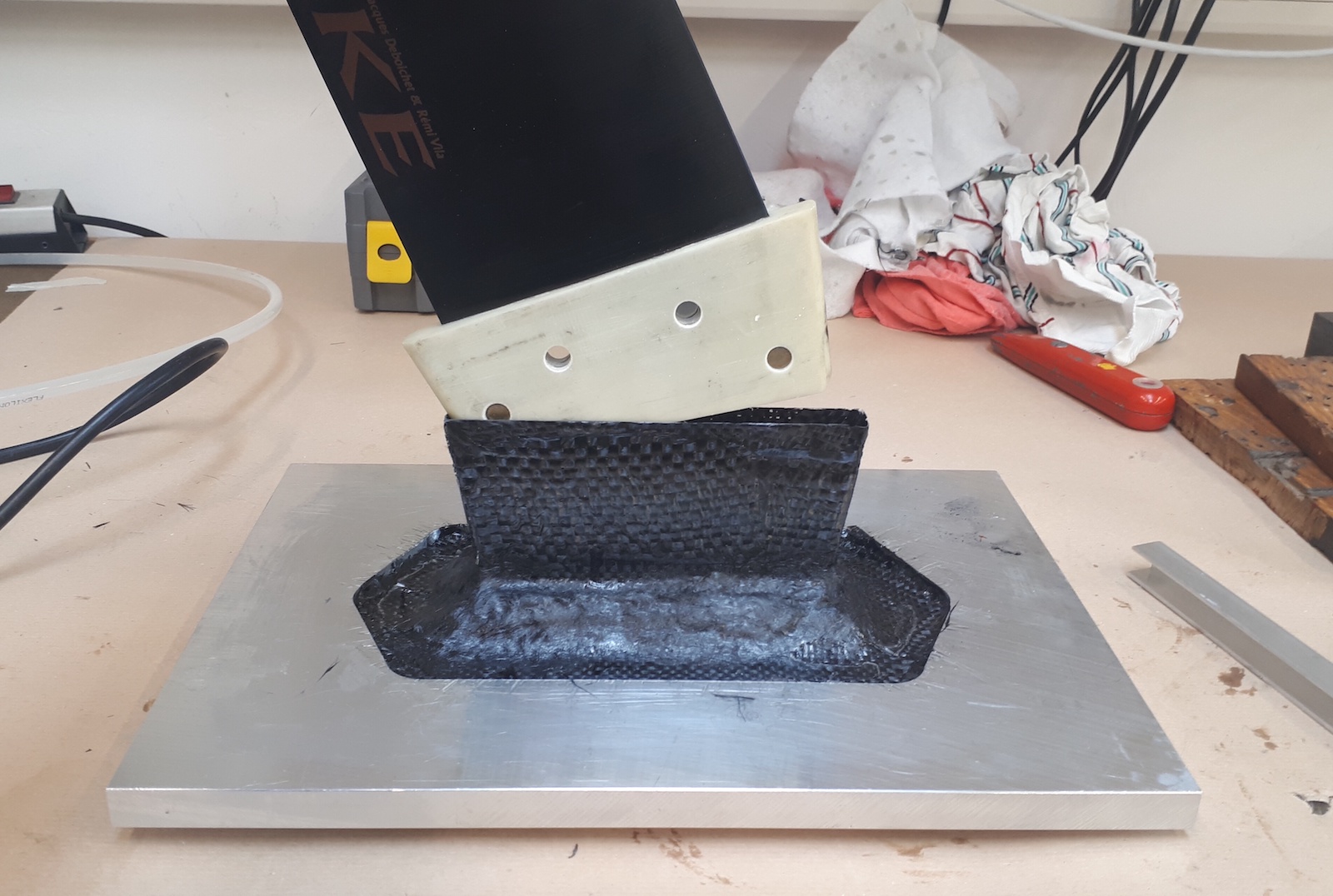

Unfortunately, I haven't taken any pictures of the manufacturing of the main mold and the spacer plate but the final result looked like this

Before laminating, all parts were coated with one layer of permanent mold release and 3 layers of mold release wax so that the finished adapter can be released from the mold when hardened. The first step was to laminate several (~12 in total) segments of 160 g/m2 and 285 g/m2 carbon fabric under vacuum into the main mold. As you will see later in the post using the 285 g/m2 carbon fabric wasn't the best idea because it is too stiff to bend into the rather sharp edges of the mold and thus left some cavities.

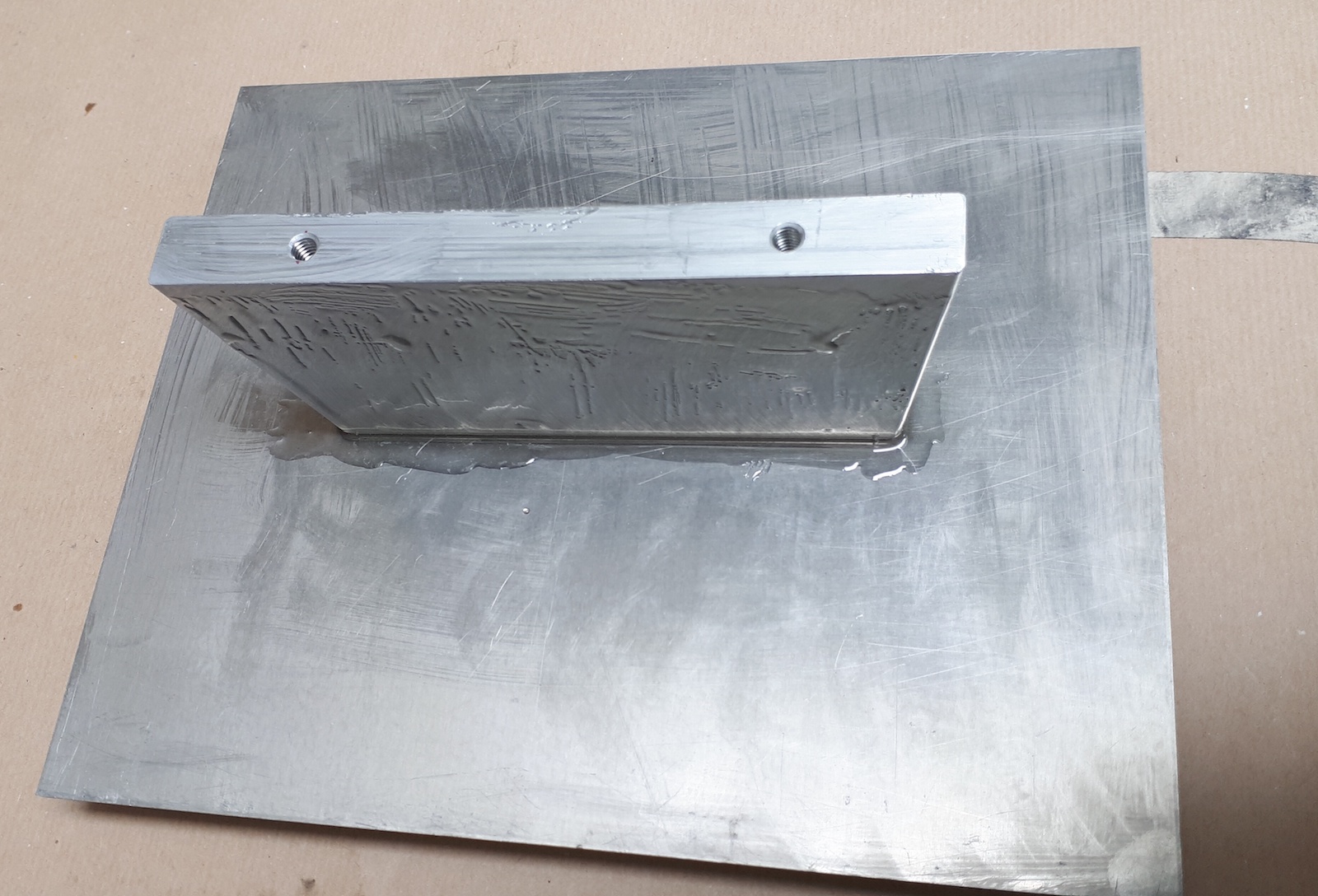

Also the deep tuttle positive was wrapped with carbon which was hardened under vacuum

after which the two parts were glued together with epoxy. I used an aluminum bar screwed to the deep tuttle positive to align and fixate the upper part of the adapter to be perfectly parallel to the bottom part.

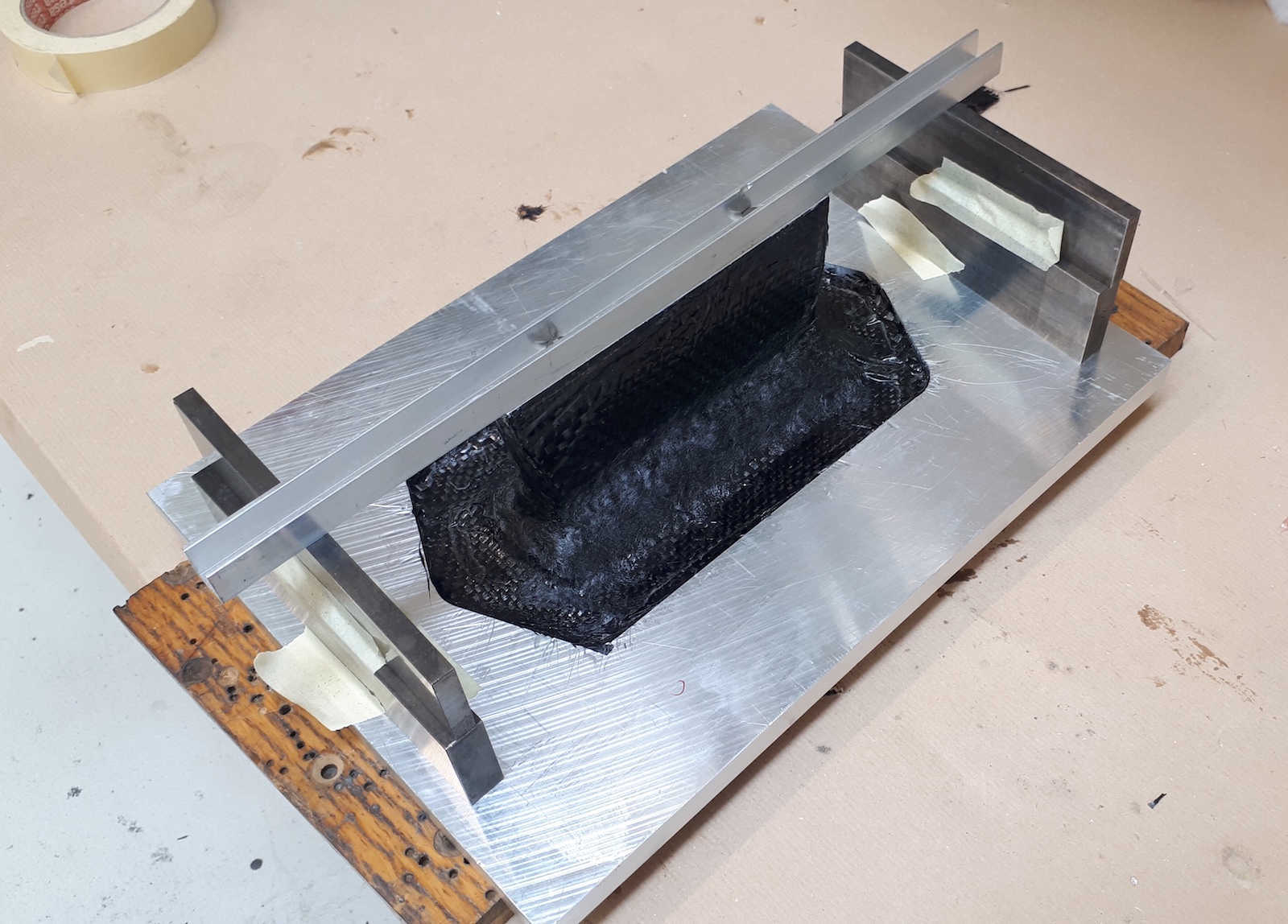

A mixture of 6 mm carbon chips and epoxy was used to hand-form a radius between the two pieces. This allows a better redistribution of forces onto the next layers when under load.

First fit test of the adapter with a cut Drake formula fin

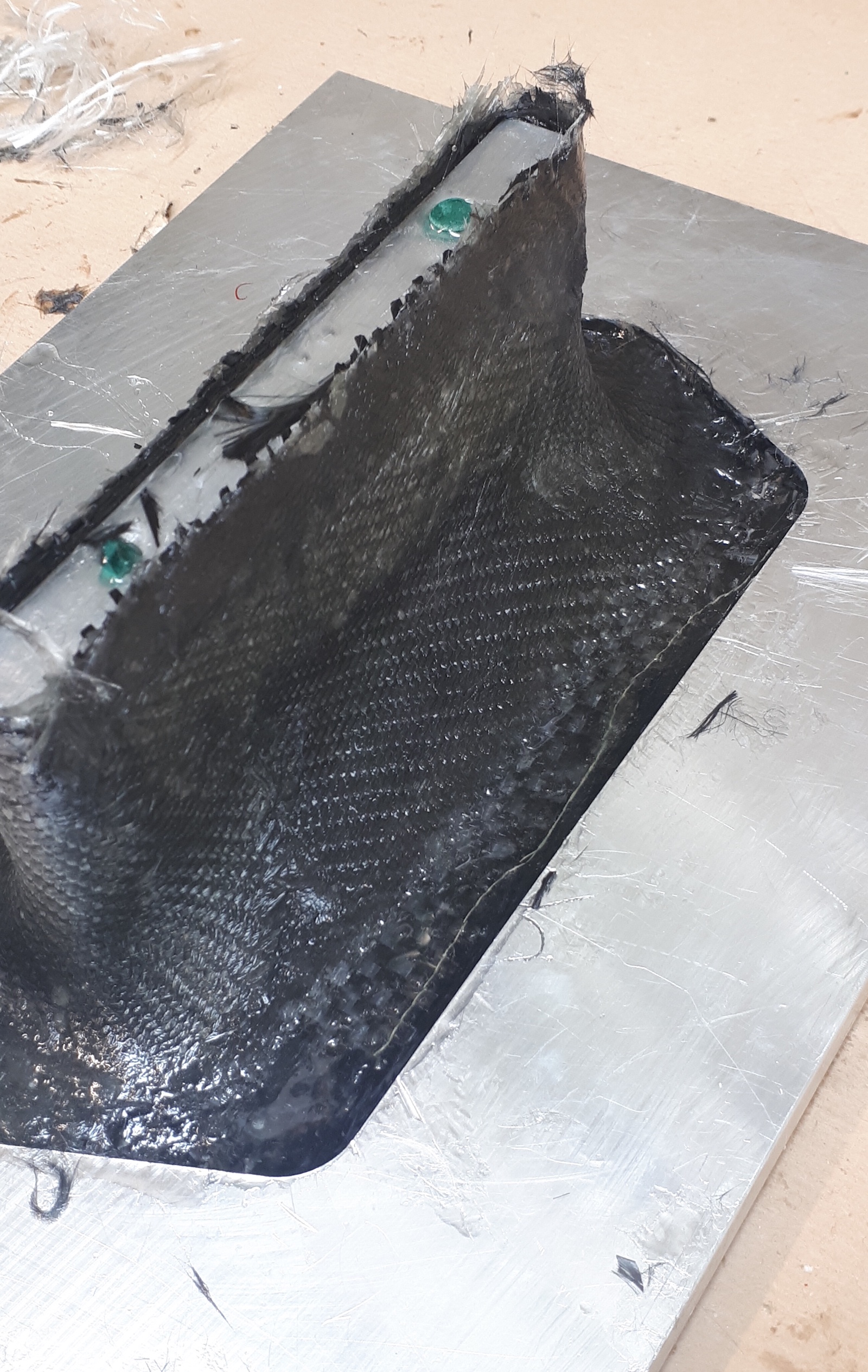

Snapshot in between adding several layers of 285 g/m2 carbon and 200 g/m2 glass fabric. Hardening these layers fixated by tape but without vacuum proved to be a mistake

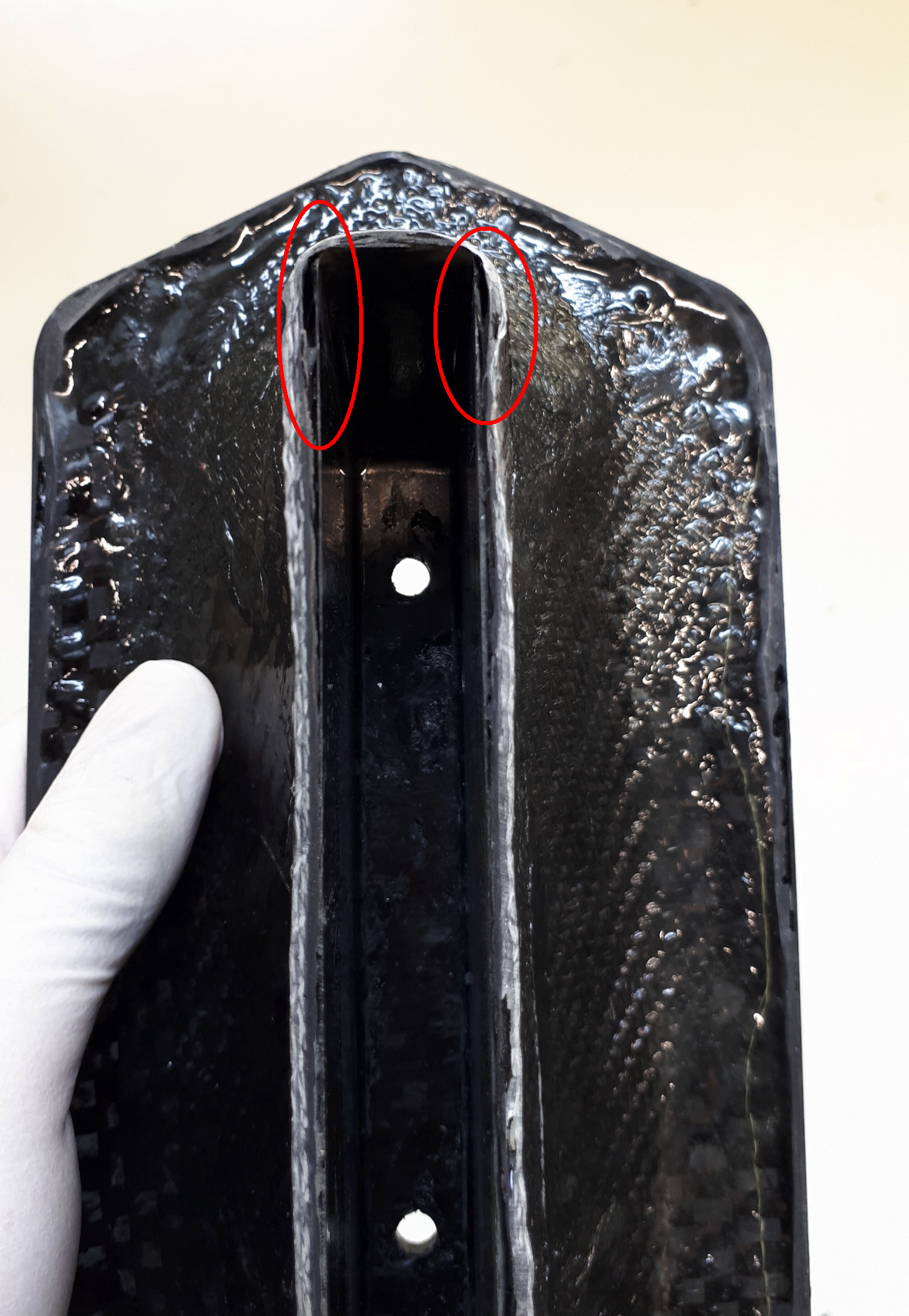

because cavities formed at the sharp corners of the tuttle head slot (marked in red).

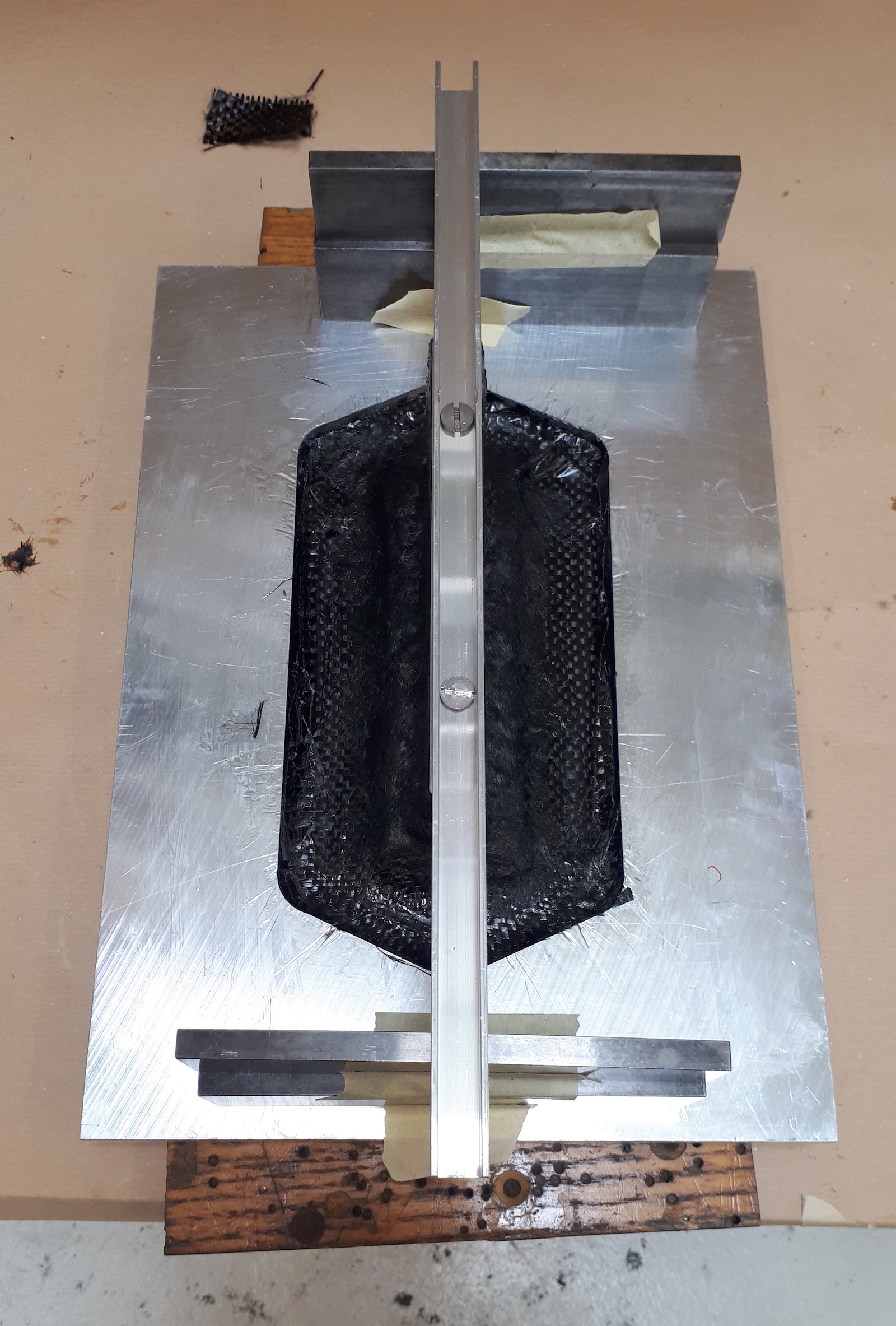

At that point, I was about to start over but then decided to try fixing it by pressing carbon fibers soaked with epoxy into the holes and laminating several belts of glass around the top for additional reinforcement. Latter I also kept doing with the next layers of carbon fiber.

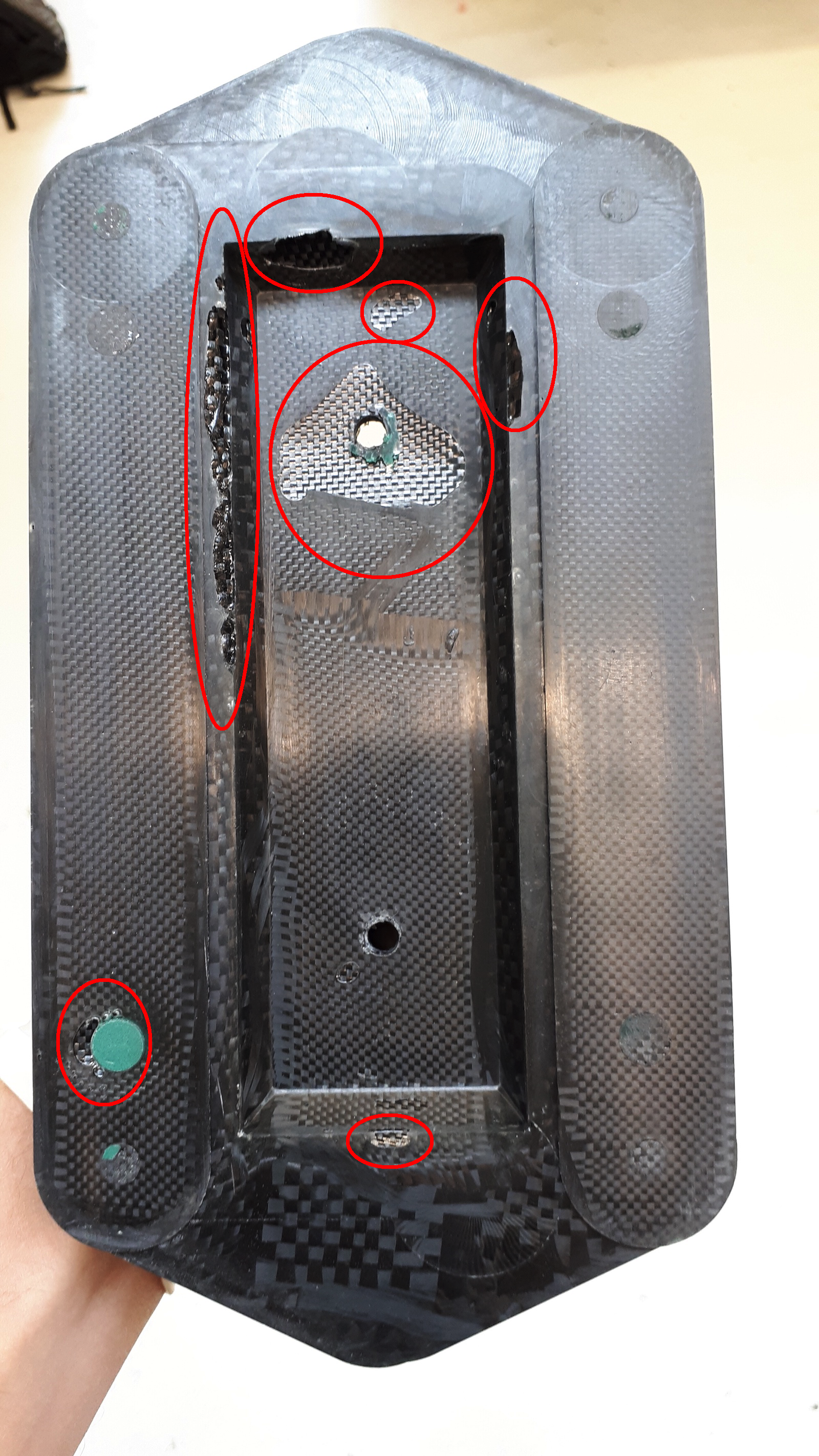

The cavities caused by the stiff carbon fabric in the main mold (also marked in red) were fixed by filling them with epoxy and putting the adapter with the spacer plate under pressure back into the main mold.

After 1 can of 6 mm carbon chips, 1/2 m2 of carbon fabric and 1/4 m 2 of glass fabric (mostly clippings), lots of epoxy and 3 laminting steps this was the intermediate result.

It took about 2 hours of sanding before the adapter was ready for its final layer or carbon fabric.

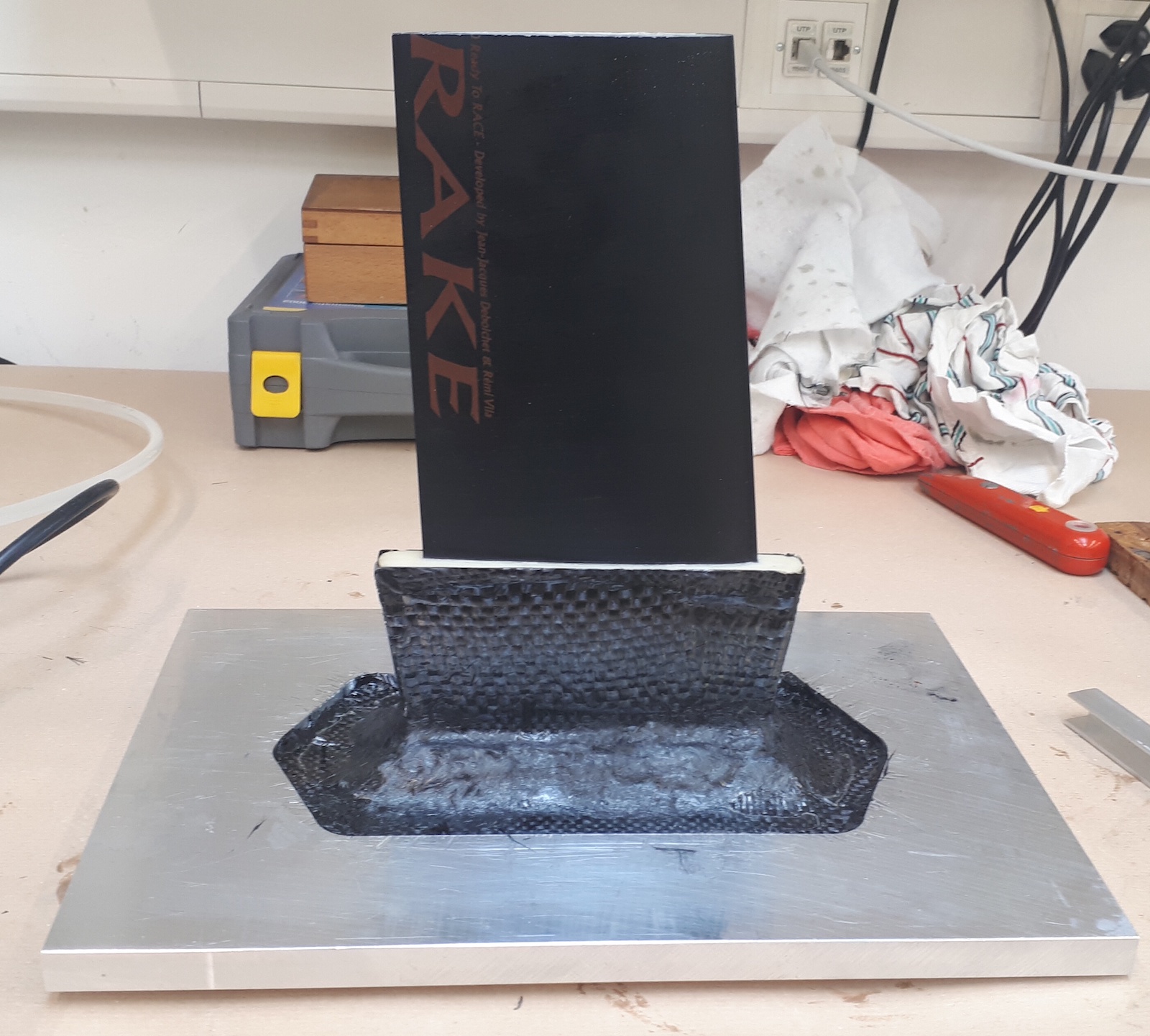

This is how it looked after the last layer was laminated under vacuum

After drilling the holes and a lots of sanding, it started to look like an adapter that could actually be used.

At first, I tried to do a glossy epoxy layer but that didn't result in a nice surface finish. So I sanded the surface smooth and coated it with a clearcoat.

The finished adapter had a weight of 675 g which is about 75 g heavier than the GROOVE Deep Tuttle Adapter which is 100% carbon. Luckily, with my 94 kg the additional 75 g won't matter that much ;) If you are wondering - the white sticker that is blurred out is my private email address that was laminated into the adapter.

Overall I am very happy with the result. Up to today, the adapter has been used in about 25 sessions including pump foiling without any issues.

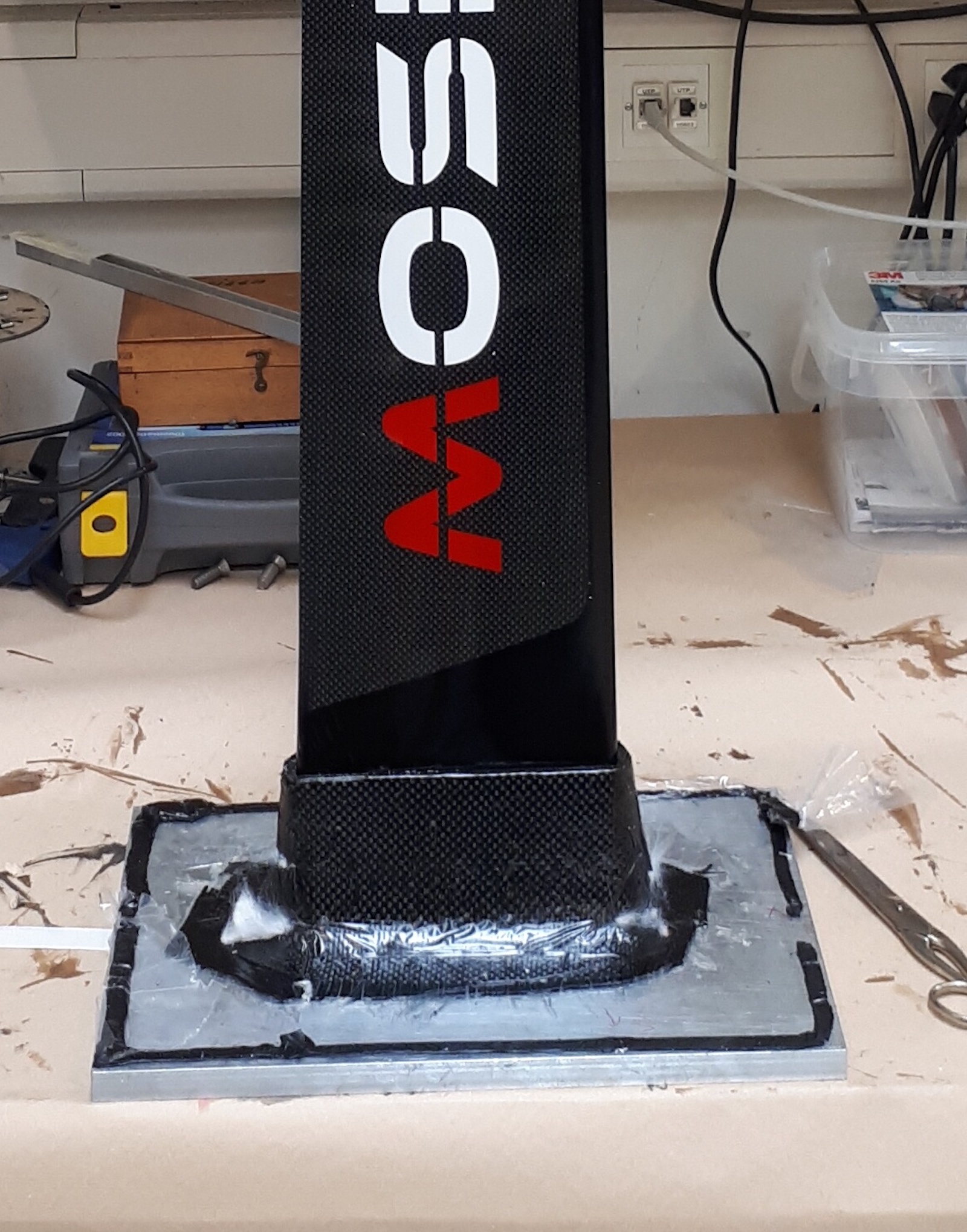

This is how the adapter looks on the foiling power plate

and on my Moses T40 foilsurf board for pump foiling

Lessons learned in this build:

- Whenever possible use vacuum when working with carbon or glass fabric. In addition to the removal of excessive epoxy which will make the part lighter, vacuum ensures that all layers are properly pressed together when hardening.

- Clearcoat on a smooth surface gives a much better finish than an additional layer of epoxy.

- Do not apply epoxy to a surface that has seen mold release wax before sanding it properly.